CFD Consulting for Heavy Industrial & Manufacturing Settings

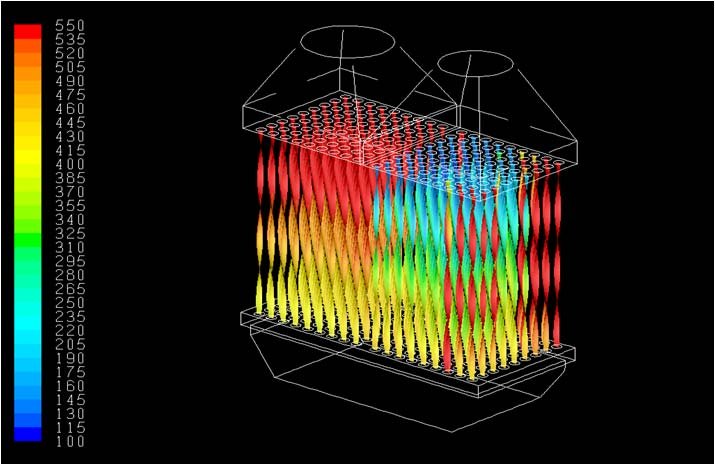

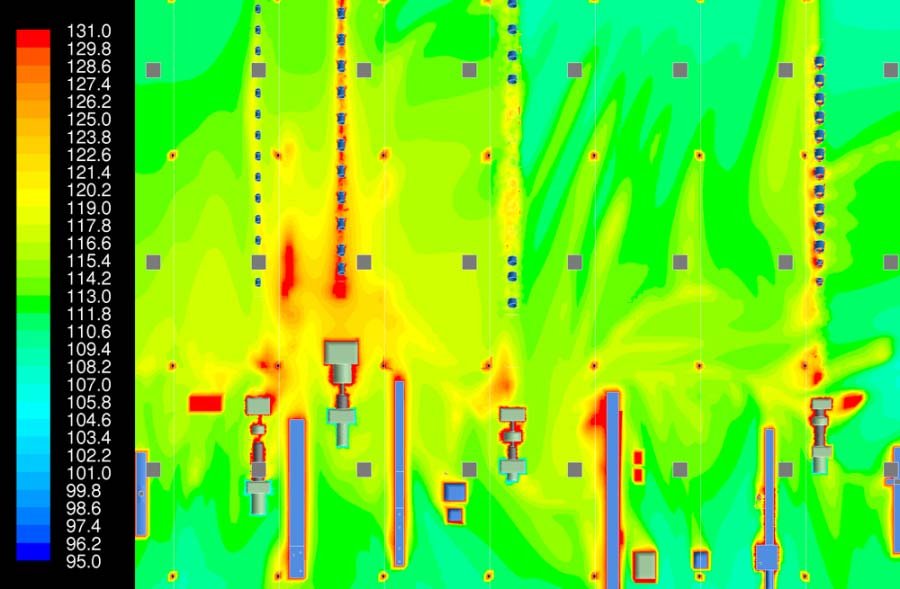

Heavy industrial applications tend to be in hot, dirty and challenging operating environments. M/E Engineering has provided CFD consulting for modeling worker comfort and safety in steel and aluminum mills, extremely uncomfortable moist, hot environments involved with paper products, drying applications using very high air velocities, quenching operations both with and without phase changes, heavy duty heat transfer in the heat exchangers of combustion air preheaters (recuperators), explosion modeling and a host of other applications.

CFD modeling provides architects and engineers the benefit of trying new ideas to improve industrial settings without the investment of prototypes or mockups. When processes or machinery are being evaluated, we can also use the CFD solution (temperature, humidity or pressures) to calculate stresses.

What we do:

- CFD simulations of heat index and Indoor Air Quality (IAQ).

- Models of manufacturing processes or machinery.

- Quenching studies and liquid processes.

- Combustion reheat and preheat studies.

- Radiative flux calculations.

- Fire models.

- Effective ventilation in challenging environments.

- Ventilation studies of very moist or dirty environments.

Spaces Modeled:

- Aluminum extrusion factory environments

- Quenching of steel sheets or ingots in steel mills

- Recuperators using exhaust to preheat combustion intakes for industrial ovens

- Comfort, heat index and absolute temperature on factory floors

- Paper mills & processing plants

- Spray coaters

- Petrochemical refineries

- Ultra-dirty environments

- Industrial ovens

- Hydraulic machinery

- Mixing tanks and stirring operations